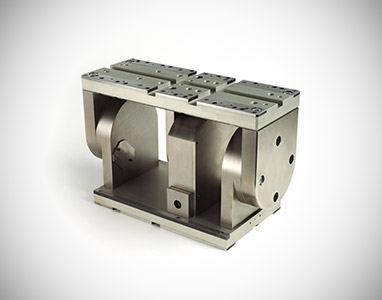

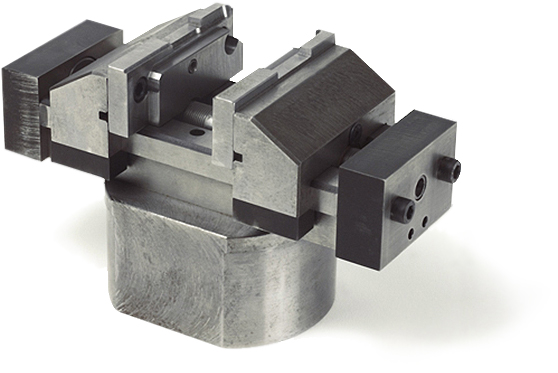

Problem-solving We develop complex system solutions

Our company solves problems from the base upwards. A cus-tomer’s idea results in a device ready for supply. We use our know-how to design devices optimally and as inexpensively as possible. This means that we can deal with design and drawing representation, material selection, purchase of standard parts and fabrication and installation of the parts at the end of the process, all from under one roof.

We can, of course, work in close cooperation with our customers on request and develop complex system solutions together.

Just contact us

Any questions? Contact us now

Springer Spann- & Zerspanungstechnik GmbH

Apfelstrasse 237

D-33611 Bielefeld

Fax: +49 (0)521.87 10 84

kontakt@springer-zerspanungstechnik.de

www.springer-zerspanungstechnik.de

Just call us

+49 (0)521.87 10 74

© Springer Spann- & Zerspanungstechnik GmbH